About Us

History of Glassform

Glassform was established in 1985 by founder and managing director Nathan Munz, in Victoria, Australia. With over 40 years experience in the glass fabrication industry, Nathan has developed Glassform as the industry leader in each product category that it supplies, providing customized glass solutions for a range of specialised applications.

Glassform has a track record of working closely with customers to determine the best solution to any set of performance criteria and being able to custom manufacture GenuinelyCertified™ product delivered in full and on time to projects in Australia, New Zealand, Asia, Europe and North America.

Glassform provides GenuinelyCertified™ unique solutions for architectural, security and transportation applications. It has a track record spanning 30 years of industry leading products and processes, developed with a unique knowledge base and a combination of in house testing and processing capabilities not available in any other glass processing facility.

Unique facilities and capabilities include:

1. Glass forming of larger and more complex shapes, including double curvature in laminated safety glass.

2. Lamination of large and complex constructions using a variety of interlayers as dictated by the application.

3. Chemical toughening of flat and curved glass of thicknesses from 1 to 25mm.

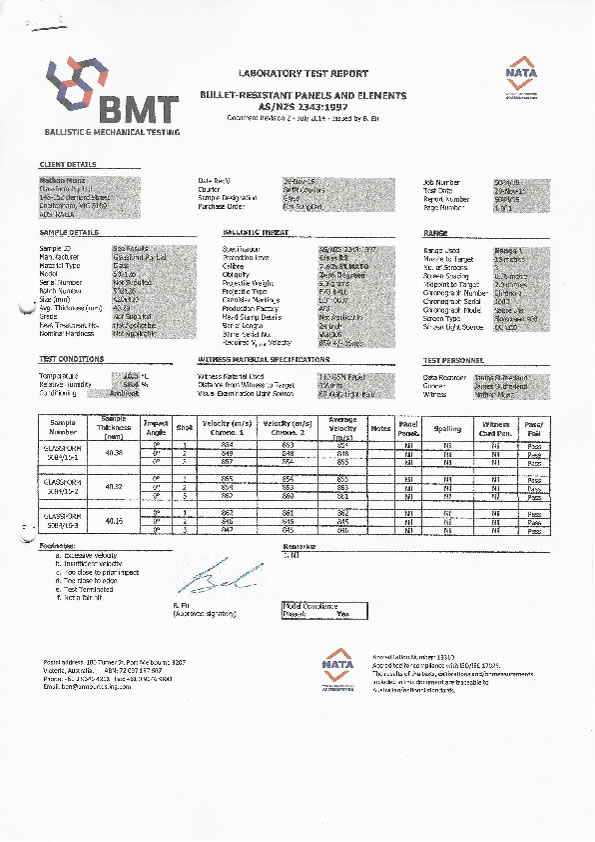

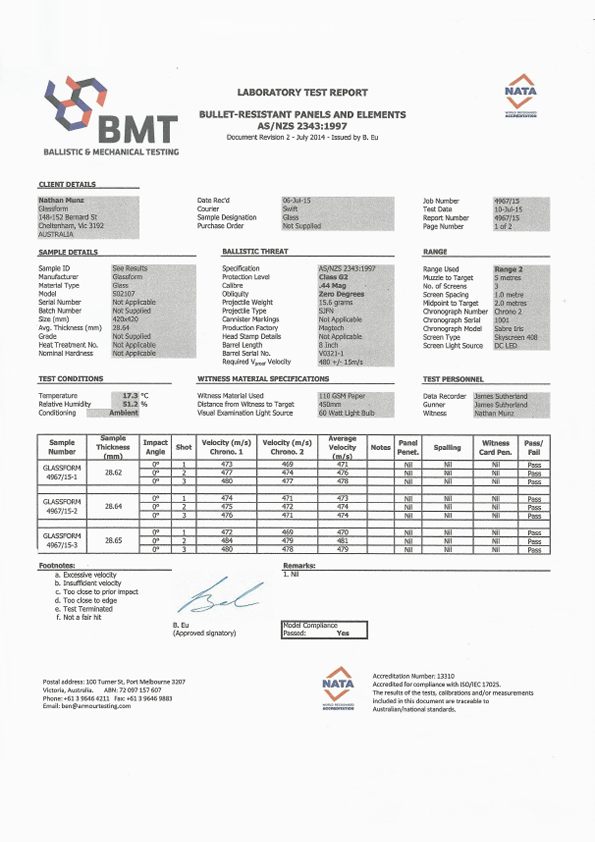

4. Calibrated and Certified in-house test facilities for glass strength, laminating interlayer quality and adhesion and conformance of finished products to safety, ballistic and impact Standards for product development and quality assurance.

Research & Development

Glassform’s rigorous research, development and technical expertise have been applied over more than 30 years to facilitate the supply of unique GenuinelyCertified™ solutions as demanded by complex requirements of architectural, rail and other applications.

Glassform’s range of test equipment, not available to any other glass processor, is critical to achieving the performance and integrity of its glass solutions.

Practical evidence of these outcomes is:

1. The industry leading 20-year delamination warranty offered by Glassform.

2. Glassform’s capability of supplying thinner, lighter and more effective blast, forced entry and bullet resistant glass without using materials which degrade with time and exposure to light.

3. Glassform’s unique range of customized GenuinelyCertified™ solutions for railway applications.

4. The shape accuracy of Glassform® curved glass in cylindrical, conical and double curvature shapes.

In-house Rail Windscreen Impact Test BRB 566

GenuinelyCertified™

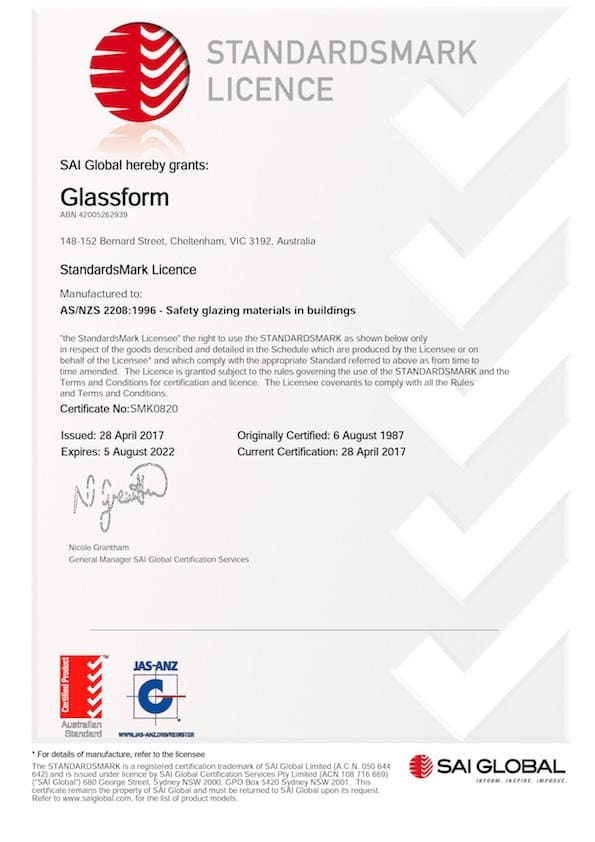

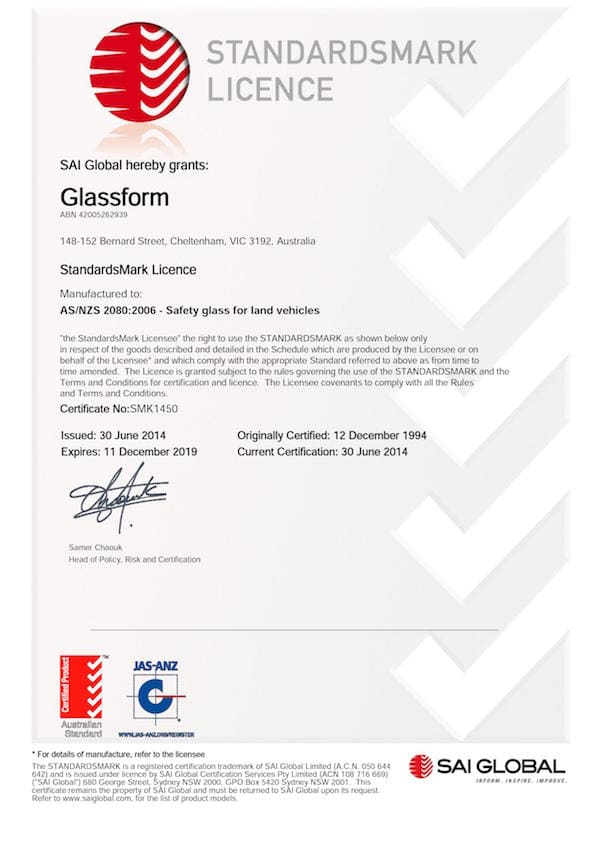

Products are GenuinelyCertified™ to Australian and International Quality and Performance Standards by accredited third party authorities, and continuing conformance is assured by regular audits, in-house and external testing in NATA certified laboratories.

Products are custom produced to comply with widely varying customer requirements including for solar control and insulation, decorative and aesthetic design and resistance to ballistic, blast and/or physical threat for commercial, residential and institutional markets throughout Australia and the world. Glassform is accredited by SAI Global to the ISO9001 Quality Standard as well as having Product Certifications to AS2208, AS2343, AS3555, AS2080, FRA Type I and II, BRB 566, GM/RT2456 and equivalent international standards.